Why Automating Batching and Filling Improves Efficiency

Manual filling and batching can lead to product waste, inconsistent weights, and costly downtime — especially when dealing with sticky or temperature-sensitive products like corn syrup, sauces, batters, or syrups.

At Peninsula Scale, we design automated filling, packaging, and blending scale systems that deliver consistent results and eliminate repetitive manual adjustments.

Case Study: Corn Syrup Filling Automation

A local candy manufacturer came to us with a simple request — fill buckets with 60 lbs of corn syrup. On paper, it sounded easy. But in practice, corn syrup viscosity changes with temperature, making timers unreliable.

- When the syrup was warmer, buckets overfilled.

- When it was cooler, buckets underfilled.

- Spills were common, causing wasted product, extra cleaning labor, and occasional production stoppages.

The Automated Weighing Solution

We implemented a scale-based automated filling system that:

- Weighs each bucket in real-time

- Automatically shuts off the pump and valve at the exact target weight

- Eliminates overfills and underfills regardless of syrup temperature or flow rate changes

Hardware Selection for Cost-Effective Automation

To balance performance and budget, we chose the Pennsylvania 7600 weight indicator with a built-in advanced batching program.

- No need for expensive custom programming

- Integrated batching logic for filling, packaging, and blending applications

- Stainless steel washdown-ready scale base with a 500 lb capacity, allowing future upgrades to fill directly into kettles

Automated Pump Control

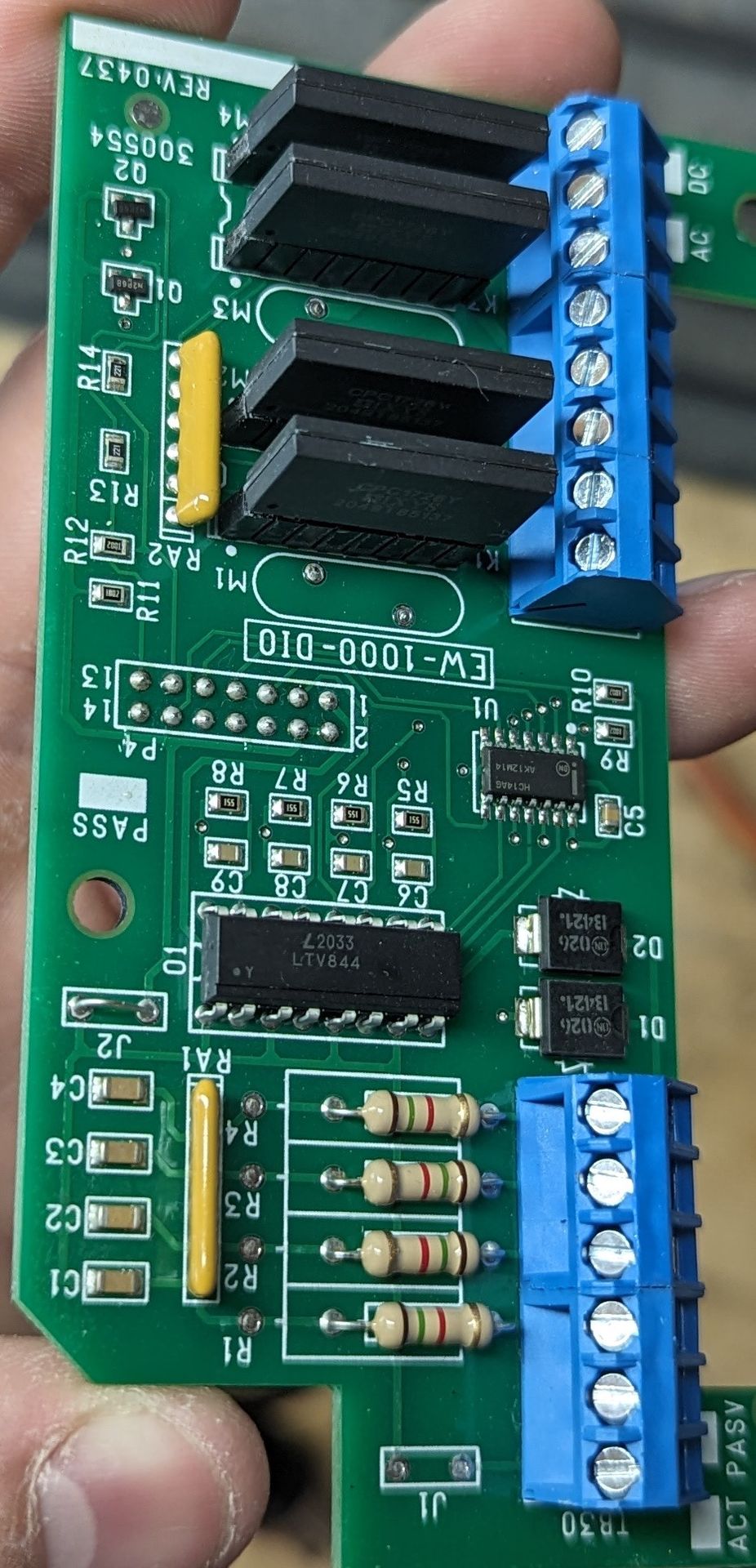

We added a digital solid-state DC relay option card to the scale to control the pump motor drive.

- Relay connects to the stop jumper on the motor drive, set to always-on mode

- Relay modules are replaceable for long-term serviceability

- AC relay options available for alternative control setups

Operator-Friendly Start/Pause Controls

To reduce keypad wear and sticky buildup from operators’ hands, we installed a remote industrial pushbutton to start and pause the batching process.

- Reduces downtime from keypad repairs

- Speeds up repetitive small-batch production

- Keeps the main scale instrument clean and functional

Applications Beyond Corn Syrup

This same automated weighing and batching setup works for:

- Food processing – sauces, syrups, batters, oils, and dry ingredient blends

- Packaging lines – filling containers, bags, or cartons by weight

- Chemical batching – mixing additives and liquids in precise proportions

- Blending systems – integrating multiple ingredient streams into a single, accurate batch

The Benefits of Automated Filling & Batching Scales

- Consistent weights for every package or container

- Reduced product waste and cleanup labor

- Faster production cycles with less operator intervention

- Improved compliance with packaging weight regulations

📞 Call Peninsula Scale today to discuss your automated filling, packaging, and blending scale needs — we’ll design a solution that fits your process, product, and budget.