The Hidden Cost of Corrosion in Food Processing Scales

In the food processing industry, scales are often used in environments where daily sanitation, high-pressure washdowns, and constant moisture are unavoidable. Add in the natural electrical currents in electronic scales and the mix of dissimilar metals, and you have the perfect recipe for electrolysis — a process that accelerates corrosion in load cells.

For facilities with stringent hygienic requirements, choosing the right load cell material can mean the difference between a scale that lasts 3 years and one that lasts 7 years or more.

Aluminum vs. Stainless Steel Load Cells

We often hear this question: “Should I choose aluminum or stainless steel load cells for my scale?”

Here’s our answer:

- If your scale will be used in wet or damp conditions — or if your facility has regular washdown procedures — always invest in stainless steel load cells.

- In our experience, 8 out of 10 aluminum load cells in washdown environments fail several years sooner than stainless steel equivalents.

Why Stainless Steel Pays Off in the Long Run

While stainless steel load cells have a higher upfront cost, the total cost of ownership tells a different story.

Consider the costs of premature scale failure:

- Lost product if weights drift without being noticed

- Rejected shipments at your customer’s dock

- Service calls with travel, labor, overnight shipping, and parts — often costing more than the stainless upgrade would have

- Production delays when operators doubt readings or swap out scales mid-shift

- Maintenance team downtime spent diagnosing scales instead of keeping critical production equipment running

What factors should I consider?

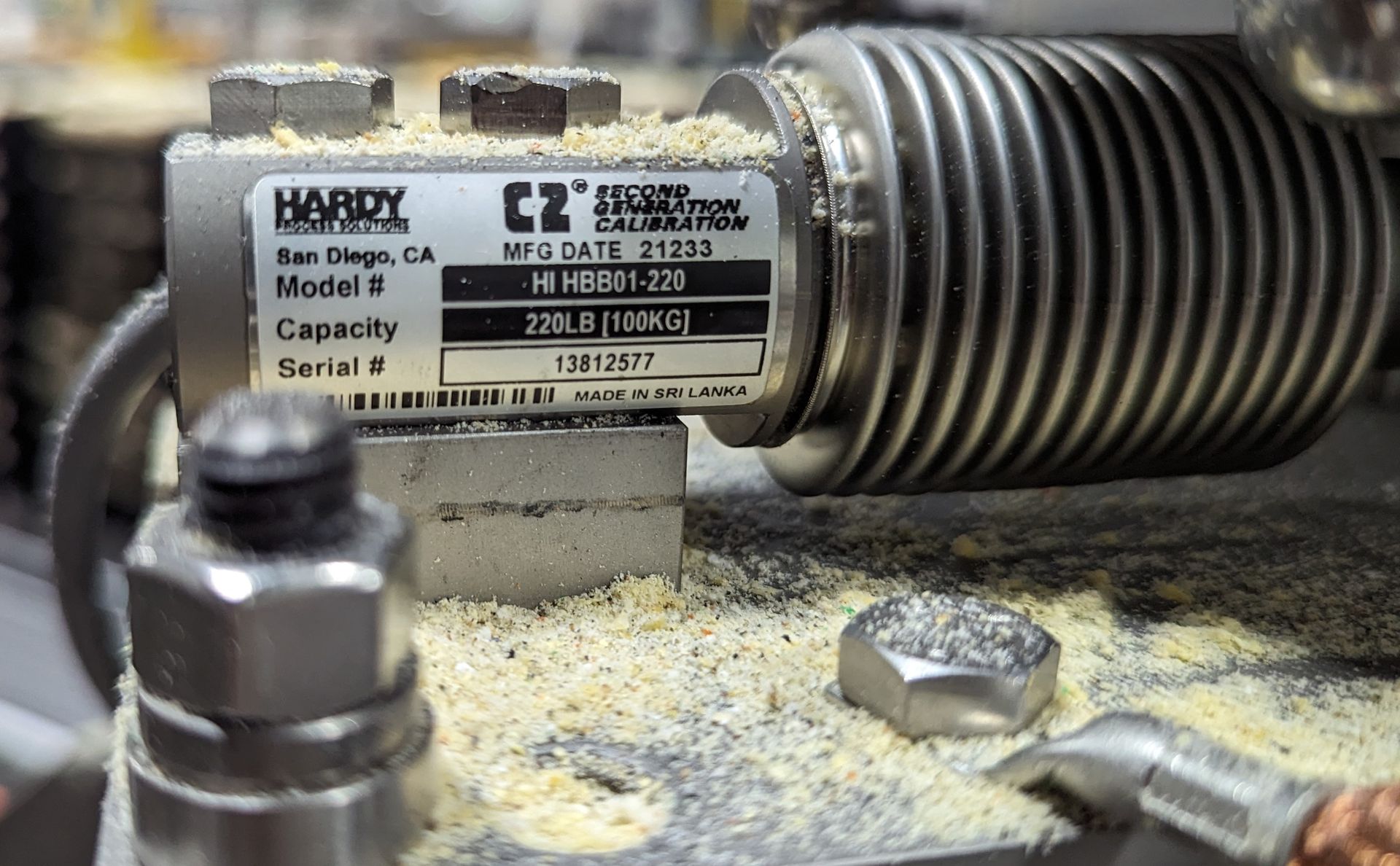

Real-World Example: Vegetable Cutting Line

We recently serviced a scale used daily to weigh onions, carrots, and peppers. The customer reported drifting weights and poor repeatability.

- The liquids from produce had accelerated corrosion on the aluminum load cell.

- Corrosion weakened the bond between the metal and potting compound, letting moisture into the sensitive strain gauge area.

- The result: premature failure and costly downtime.

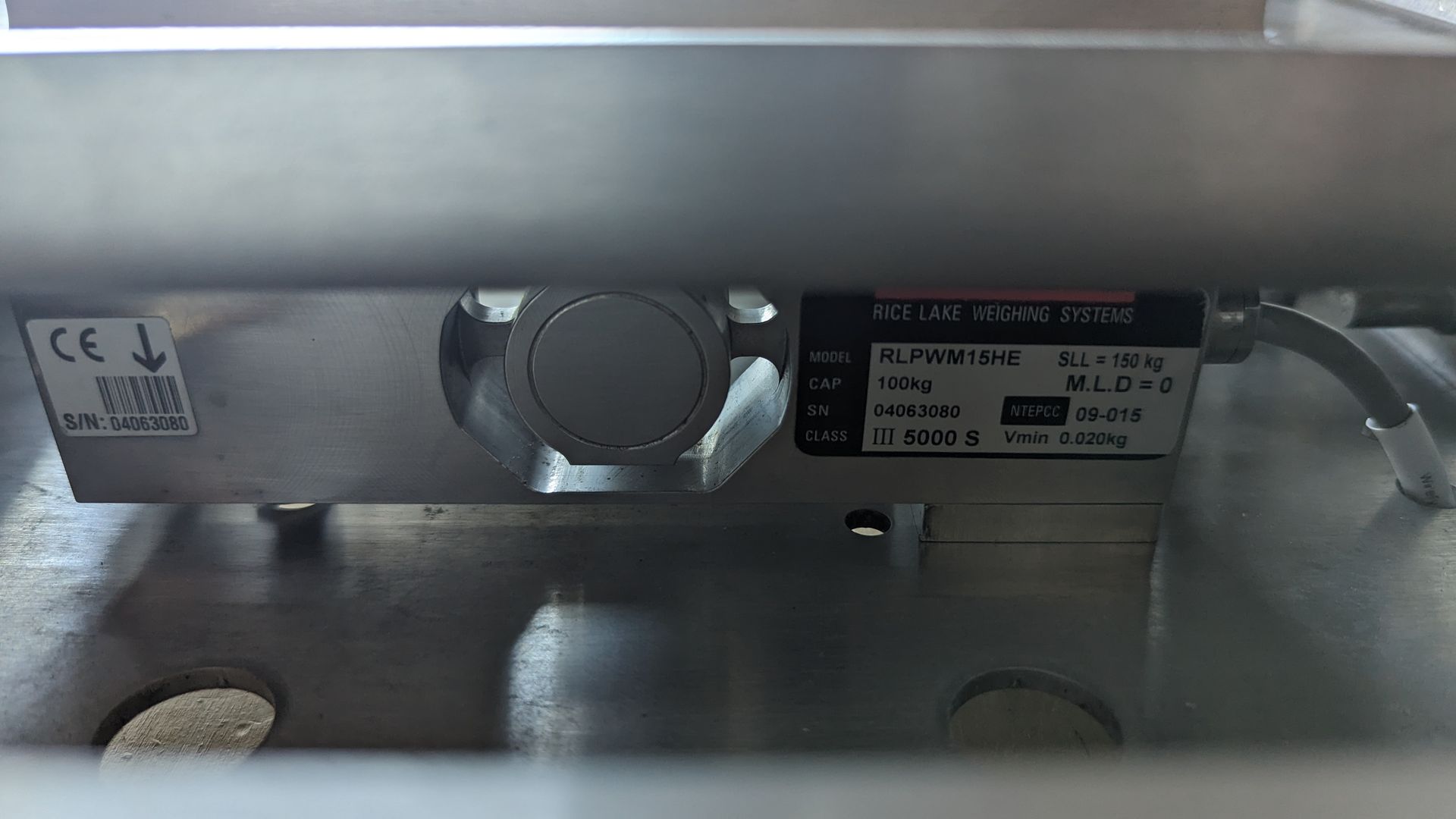

How Hermetically Sealed Stainless Steel Load Cells Help

Many stainless steel load cells are hermetically sealed using welded stainless bellows. This:

- Protects electronics from moisture intrusion

- Prevents delamination of the potting compound

- Extends the usable life of the load cell in harsh washdown environments

These designs are most common in higher capacity applications like floor scales, hopper scales, and silo scales.

What About Non-Electronic Load Cells?

While nearly all load cells today use electronic strain gauges, hydraulic load cells can eliminate electronics at the wet end of the scale.

- These use a rubber diaphragm filled with glycol solution.

- Force from the scale deck creates pressure in the fluid, which is routed via stainless steel tubing to a safe, dry location.

- There, a single electronic load cell converts the pressure into a weight reading.

Even here, stainless steel components protect against long-term corrosion.

Our Recommendation for Food Processing Facilities

If you operate in a high-moisture, high-pressure washdown environment, upgrading to stainless steel load cells is one of the best investments you can make. You’ll get:

- Longer equipment life

- Reduced downtime

- Better audit readiness

- Lower long-term costs

📞 Call Peninsula Scale today to discuss stainless steel load cell upgrades and washdown-ready scale solutions for your food processing facility.