Why Precision Weighing Matters in Chemical Manufacturing

In chemical manufacturing and formulation, accurate weighing is critical. From raw material dosing to final batch blending, a high-capacity tank or hopper scale that’s out of tolerance can lead to:

- Off-spec product requiring costly rework

- Safety risks from incorrect ingredient ratios

- Delays in production schedules

- Increased scrap and waste costs

When your tank or hopper load cells aren’t performing, you need a service provider who can diagnose the real issue — not just start swapping parts

The Case: 50,000 lb High-Capacity Mixing Tank

A chemical manufacturer contacted us about a 6-load cell, 50,000 lb net weight tank used in their production process. Their previous service provider had recommended:

- Two new load cells

- Two new junction boxes

- Possibly a new weight indicator

We suspected this “shotgun approach” could mean unnecessary parts replacement — and unnecessary downtime. So we went in with the right tools and no assumptions.

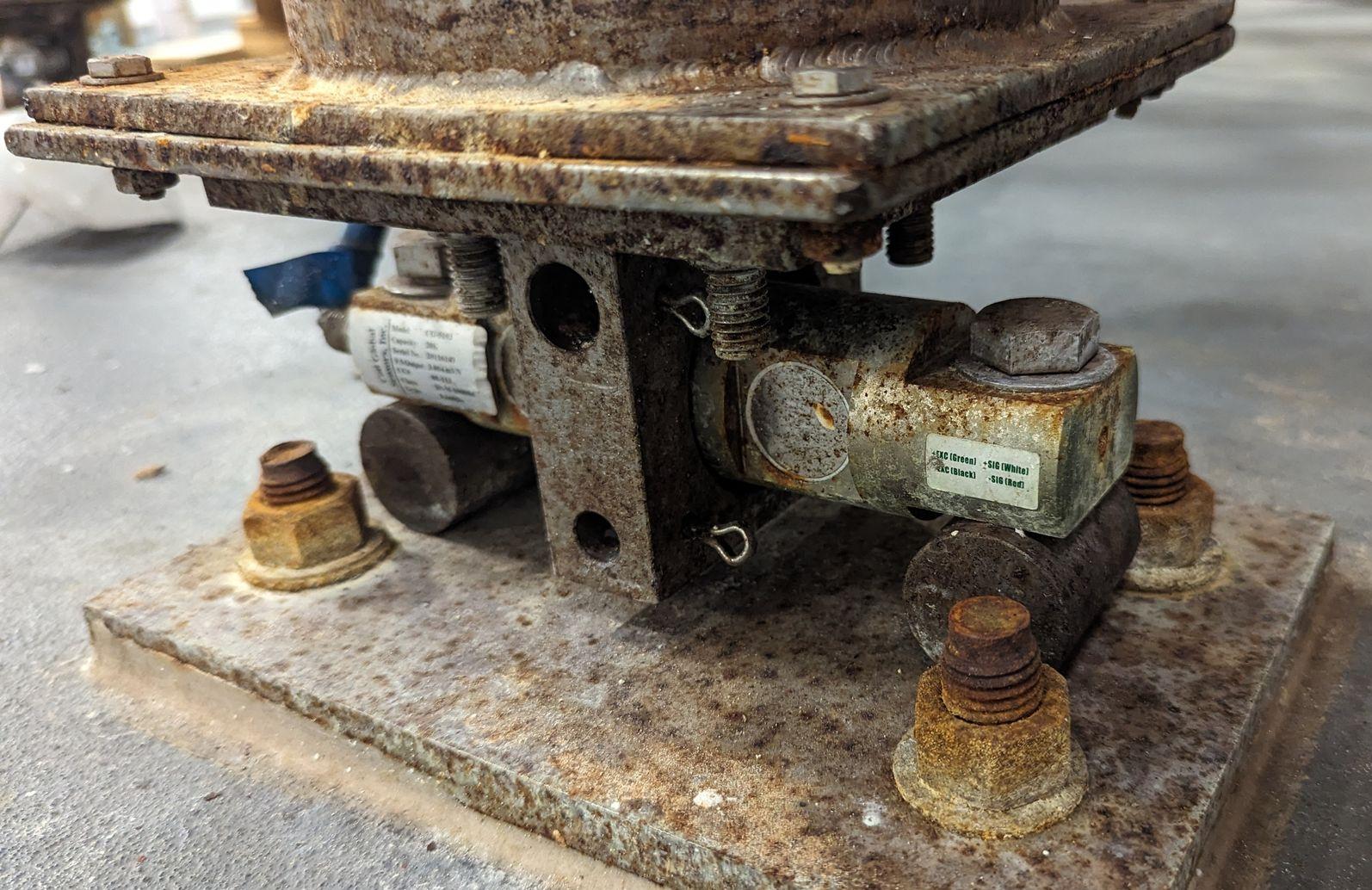

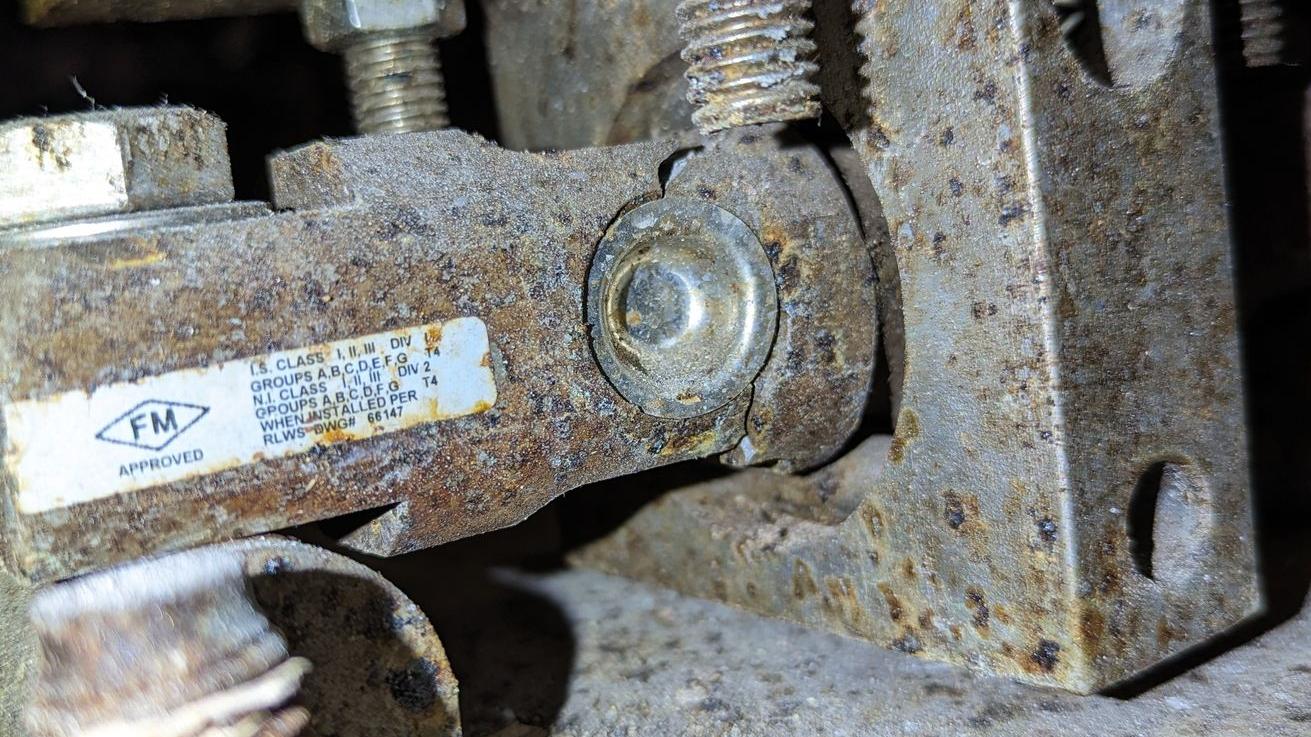

Step 1: Mechanical & Physical Inspection

Before touching any wiring, we always start with a thorough physical inspection. This often reveals:

- Mounting issues

- Physical damage from overloading or corrosion

- Misalignment or structural interference

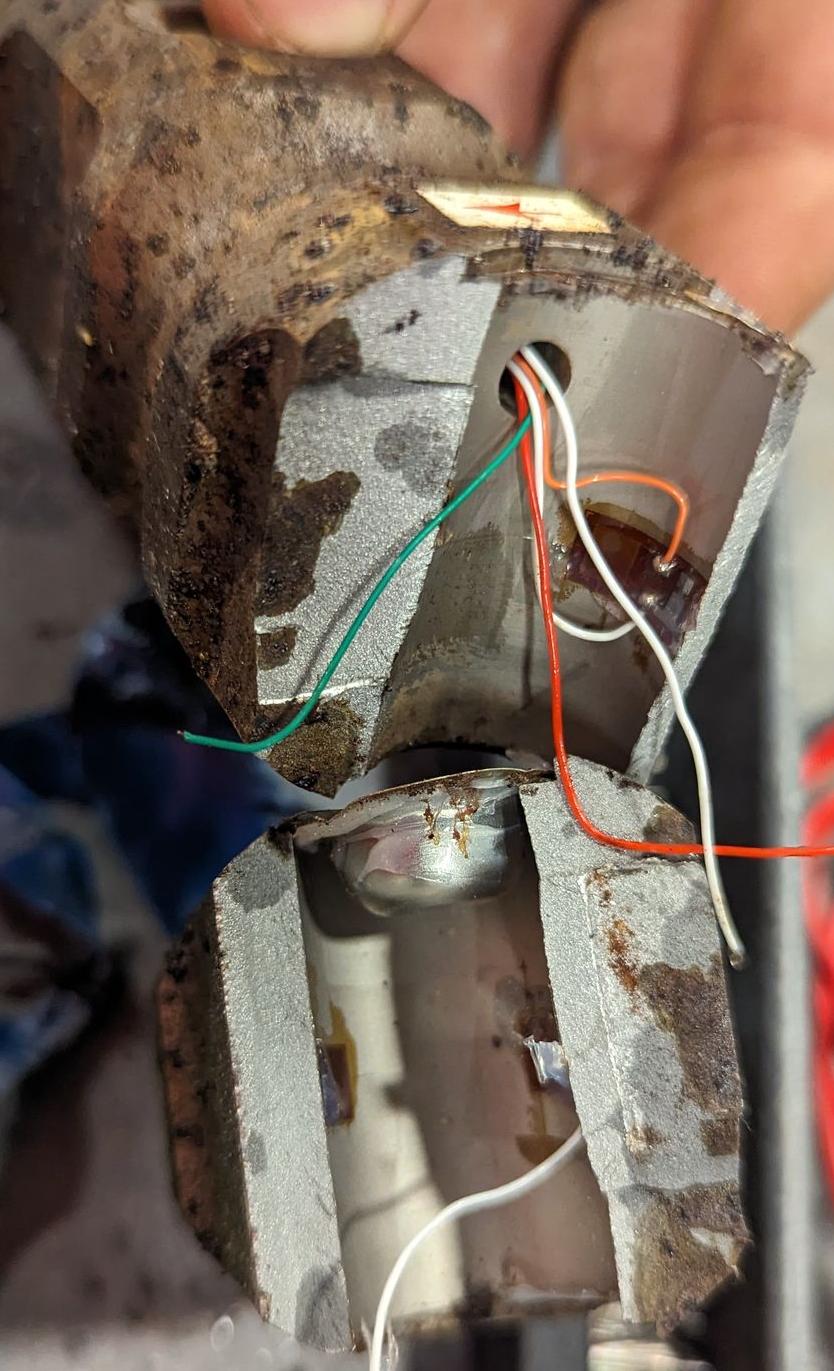

In this case, we discovered a cracked load cell body. It wasn’t obvious without a bright inspection light and crawling under each mount to check. The failure had caused the tank to lift slightly on that corner, unloading another cell and creating a false zero reading — which the previous service company had mistaken for a bad cell.

Step 2: Targeted Repairs

We replaced the single damaged load cell. No junction boxes or indicators were needed. By avoiding unnecessary part swaps, we:

- Reduced downtime

- Lowered repair costs

- Restored weighing accuracy quickly

Step 3: Improving Calibration Setup

Accurate calibration requires applying certified test weights to the tank in a controlled way. But like many batching environments, this facility had:

- Limited space around tanks

- No flat or safe surfaces for test weight placement

Initially, the only viable location was the top rim — fine for small vessels, but not safe or accurate for a 50,000 lb tank.

Step 4: Permanent Calibration Mounts

Following our recommendation, the customer’s in-house welder fabricated bolt-on weight mounts that wrap around the tank legs.

- Allows quick installation for future calibrations and can be removed during production to save space and avoid injury to staff

- Supports 4,000 lbs of NIST-certified test weight safely

- Enables targeted loading of 1,000 lbs over a single load cell for diagnostics

This upgrade not only improved accuracy for the repaired tank, but also created a facility-wide standard for all future load cell calibrations.

The Results

- Single load cell replacement restored full system function

- Improved calibration setup ensures better batching accuracy

- Reduced long-term service costs and downtime

- Higher confidence in formulation precision for every batch

📞 If you operate a chemical manufacturing or formulation facility, Peninsula Scale can help with:

- High-capacity tank and hopper scale troubleshooting

- Load cell repair and replacement

- Calibration system upgrades for safer, faster, more accurate span testing

- Batching and blending scale optimization